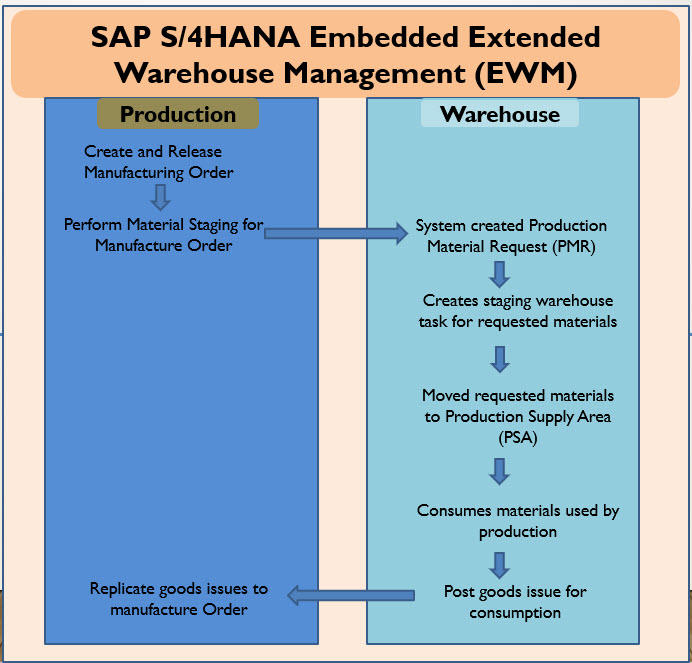

In the realm of supply chain management, efficient production planning and execution are vital for optimizing operations and meeting customer demands. SAP S/4HANA Extended Warehouse Management (EWM) offers a comprehensive solution for integrating advanced production processes, enabling seamless coordination between production and warehouse management. In this blog post, we will explore the benefits and capabilities of SAP S/4HANA EWM-Advanced Production Integration and provide coding examples to illustrate its implementation.

Coding examples of SAP S/4HANA EWM-Advanced Production Integration

SAP S/4HANA EWM-Advanced Production Integration enables real-time visibility and control over production processes, enhancing efficiency and reducing lead times. With this integration, you can synchronize material requirements planning (MRP) with production orders, automatically generate warehouse tasks, and optimize resource utilization. By streamlining production processes, you can minimize bottlenecks, improve throughput, and ensure timely delivery of products.

- Integration with Advanced Production Integration Models:

SAP S/4HANA EWM supports various production integration models, such as Advanced Production Integration (APOC), Manufacturing Execution System (MES), and Production Integration Cockpit (PIC). These models facilitate seamless data exchange and process integration between production and warehouse management systems, enabling real-time visibility and control over inventory, materials, and production orders.

To illustrate the integration between SAP S/4HANA EWM and advanced production, let’s consider an example of automatic warehouse task creation when a production order is released. In this scenario, we can use a user exit or Business Add-In (BAdI) to trigger the creation of warehouse tasks based on the production order’s material requirements.

DATA: lv_production_order TYPE afpo-aufnr.

lv_production_order = <production_order_number>.

CALL FUNCTION ‘BAPI_TRANSACTION_COMMIT’

EXPORTING

wait = ‘X’.

CALL FUNCTION ‘BAPI_PRODORD_RELEASE’

EXPORTING

order = lv_production_order.

lv_production_order.

- Updating Warehouse Task Status:

Another essential aspect of this is updating the status of warehouse tasks based on production progress. The following example demonstrates how you can update the warehouse task status once the production order is confirmed.

DATA: lv_production_order TYPE afpo-aufnr,

lt_warehouse_tasks TYPE TABLE OF ltap,

ls_warehouse_task TYPE ltap.

lv_production_order = <production_order_number>.

SELECT * FROM ltap INTO TABLE lt_warehouse_tasks

WHERE production_order = lv_production_order.

LOOP AT lt_warehouse_tasks INTO ls_warehouse_task.

ls_warehouse_task-status = ‘C’.

MODIFY ltap FROM ls_warehouse_task.

ENDLOOP.

CALL FUNCTION ‘BAPI_TRANSACTION_COMMIT’

EXPORTING

wait = ‘X’.

- Real-Time Visibility and Analytics:

It provides real-time visibility into inventory, materials, and production orders. This real-time data can be leveraged for advanced analytics and reporting, enabling proactive decision-making, optimization of resource allocation, and identification of bottlenecks or inefficiencies in production and warehouse processes.

Conclusion:

SAP S/4HANA EWM-Advanced Production Integration offers a powerful solution for streamlining production processes and optimizing warehouse management. By integrating production orders, materials, and inventory data, businesses can achieve real-time visibility, improve operational efficiency, and enhance customer satisfaction. The coding examples provided in this blog post demonstrate how SAP S/4HANA EWM seamlessly integrates with advanced production systems, enabling automated warehouse task creation and real-time updates. Embracing SAP S/4HANA EWM-Advanced Production Integration can help businesses unlock new levels of efficiency and agility in their supply chain operations.